Transform urban spaces with our modern mid-rise prefabricated buildings. Combining contemporary design with engineered strength, our solutions allow for multi-story residential, office, or commercial projects with minimal on-site disruption. From planning and production to installation, every step is designed to deliver quality, safety, and aesthetic appeal. Discover how our mid-rise buildings can elevate your project today.

Mid-rise prefabricated buildings are multi-story structures constructed from factory-manufactured modular units. Typically ranging from 4 to 10 floors, these buildings are engineered for fast assembly without compromising structural integrity. They are widely used for residential complexes, office buildings, hotels, and commercial facilities where both speed and durability are critical.

S-CAS prioritizes prefabricated construction using modern methods, offering a significant speedup and improvement in construction accuracy compared to precast and cast-in-place concrete. Furthermore, it offers the following advantages:

S-CAS is 75% lighter than reinforced concrete, increases live load capacity, and is typically between 1 and 3 inches thick.

Contact AkoetechCCP wall panels are used as exterior wall panels, interior wall panels, floor panels, roof panels, and floor slabs, allowing for seamless construction of houses.

Compared with traditional cast-in-place construction, our low-rise prefabricated building system reduces overall construction time by over 40%, while maintaining high structural strength, durability, and long-term performance.

Get a Quote Now

Engineered mid-rise buildings for residential, commercial, public, and industrial projects, combining safety, efficiency, and sustainability

_1766456645_WNo_600d400.jpg)

Mid-rise prefabricated residential buildings, typically 4–8 floors, designed for urban living with modular layouts, rapid construction, and high structural integrity.

_1766456690_WNo_600d400.jpg)

Designed for multi-story commercial use, these prefabricated buildings allow flexible floor plans, fast on-site assembly, and meet seismic and load-bearing standards.

_1766456710_WNo_600d400.jpg)

Multi-story public buildings engineered for rapid deployment and safety, offering 4–7 floors with modular classrooms, medical spaces, or community halls.

_1766456734_WNo_600d400.jpg)

Mid-rise industrial prefabricated buildings designed for warehouses and light manufacturing, offering 3–6 floors with high load capacity and rapid modular installation.

_1766456780_WNo_600d400.jpg)

Prefabricated mid-rise buildings for temporary housing, disaster relief, and construction sites, engineered for quick multi-story assembly and structural safety.

Notes: Due to confidentiality agreements with our clients on most building projects, we are only able to showcase a selected number of low-rise prefabricated building designs. All displayed projects have been shared with full consent from our clients.

Low-cost worldwide shipping, 10-minute installation by anyone, rapid mass production capability

Find the best solution for your project and check our detailed pricing table for guidance.

_1772086089_WNo_564d376.jpg)

_1772086110_WNo_892d595.jpg)

_1772086141_WNo_1000d666.jpg)

| For a typical two storey 2152ft² house | Light Gauge Steel House | Integrated Modular House | S-CAS CCP House | |

| Economic benefits | Overall cost (USD per ft²) | 100% | 120% | 80% |

| Interior spatial flexibility | Limited space,minor layout adjustment | Limited space, fixed layout | Large space, flexible layout and adjustment | |

| Overall construction period | 20-25 days | 7-9 days | 7-9 days | |

| Quality | Seismic/wind resistance | Potential risk | Potential risk | Excellent |

| Fireproofing | 4 hours | 4 hours | More than 5 hours | |

| Waterproofing | Aging problem at the seams | Potential risk of leaking at the seams | Anti-aging, prefabricated waterproof seam treatment | |

| Moisture/mildew proofing | Average | Average | Excellent | |

| Soundproofing | 45dB, hollow feeling | 45dB, hollow feeling | 52dB, solid feeling as concrete | |

| Service life | 30 years | 30 years | 100 years | |

| Manufacture | Production period | 5 days | 15 days | Less than 1 day |

| Quantity of labor | 10 | 15 | 6 | |

| Quality of labor | Skilled and specialized workers | Skilled and specialized workers | Ordinary workers | |

| Production capacity (Monthly) | 30-40 units | 50-70 units | 150-200 units | |

| Transportation | Efficiency | High | Low | High |

| Cost | Low | High | Medium | |

| Main structure installation | Period | 15 days | 2 days | 2 days |

| Quantity of labor | 15 | 6 | 6 | |

| Quality of labor | Various specialized workers | Various specialized workers | Ordinary workers | |

| Internal decoration installation | Period | 10-15 days | 5-7 days | 6-7 days |

| Quantity of labor | 10-12 | 5-6 | 6-8 | |

| Reusability and recyclability | Main structure | Nonrecyclable | Nonrecyclable | Recyclable |

As a leading provider of mid-rise prefabricated building systems, we deliver integrated solutions from design and engineering to manufacturing and on-site assembly. Partnering with us ensures efficient construction, optimized costs, and robust structural performance suitable for multi-story projects.

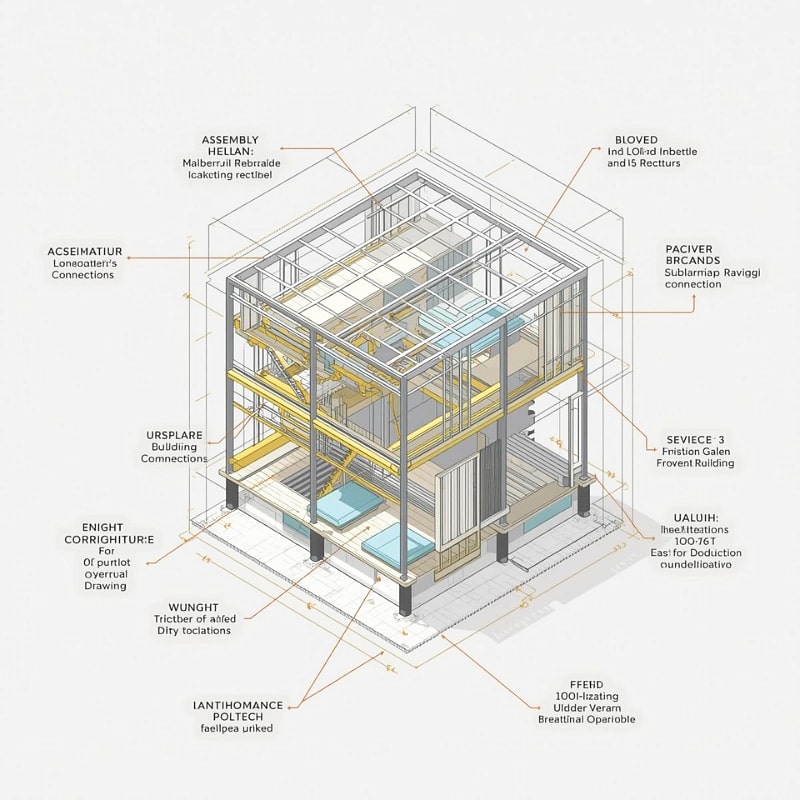

Our mid-rise prefabricated solutions include load-bearing walls, floor slabs, roof panels, and structural modules, engineered for seamless multi-story assembly.

Factory-fabricated modules reduce on-site labor and enable assembly of 2–3 floors per week, shortening construction timelines for mid-rise buildings by up to 35–50%.

Engineered for multi-story applications, our prefabricated systems meet seismic standards up to magnitude 7.0 and support live loads of 2–2.5 kPa, ensuring long-term stability and safety.

Modular production minimizes material waste and labor costs, improving budget efficiency for mid-rise residential, commercial, and industrial projects.

Modular units can be combined to create diverse layouts, easily expanded or customized to meet the functional needs of multi-story residential, office, and public buildings.

Our mid-rise prefabricated projects have been successfully delivered worldwide, complying with international building codes and supporting complex multi-story requirements.

Mid-rise prefabricated buildings are typically designed for 4–10 floors. The maximum height depends on the structural system, seismic and wind load requirements, and local building regulations. With advanced engineering, some projects can even reach 12 floors.

Absolutely. These buildings are engineered as long-term structures. When designed and installed according to standards, their service life can exceed 50 years, with robust performance for multi-story applications.

Factory-produced modules significantly reduce on-site labor. After completing the foundation, structural assembly for mid-rise buildings can progress at 2–3 floors per week, shortening overall construction timelines by 35–50%.

Yes. Conduits, piping routes, and pre-cut openings can be incorporated into wall and floor modules, reducing on-site installation errors and labor for multi-story projects.

Certainly. Floor plans, room dimensions, façade finishes, and structural configurations can be tailored to project needs, code requirements, and local climate conditions.

Although prefabricated mid-rise buildings may have slightly higher material costs, total project expenses are usually lower due to reduced labor, faster timelines, and fewer on-site uncertainties.

Foundations are typically reinforced concrete raft slabs or pile-supported foundations, depending on soil conditions and building load. Structural engineers determine the appropriate type for each multi-story project.

Yes. The modular design allows for vertical or horizontal expansion, interior reconfiguration, or functional upgrades with minimal disruption to the existing structure.

When properly engineered, mid-rise prefabricated buildings meet stringent seismic and wind load standards. Structural calculations are customized for regional requirements, ensuring multi-story safety.

Yes. We offer detailed drawings, step-by-step installation manuals, and remote or on-site technical assistance to ensure accurate assembly and smooth project delivery for mid-rise buildings.