If you're looking for a reliable provider of low-rise modular buildings or custom low-rise prefabricated building services, we offer a one-stop solution from design and manufacturing to installation. Whether it's a residential, office, or commercial facility, our rapid-assembly low-rise modular buildings can meet your project needs. Contact us today to learn about our professional solutions and easily realize your architectural dreams!

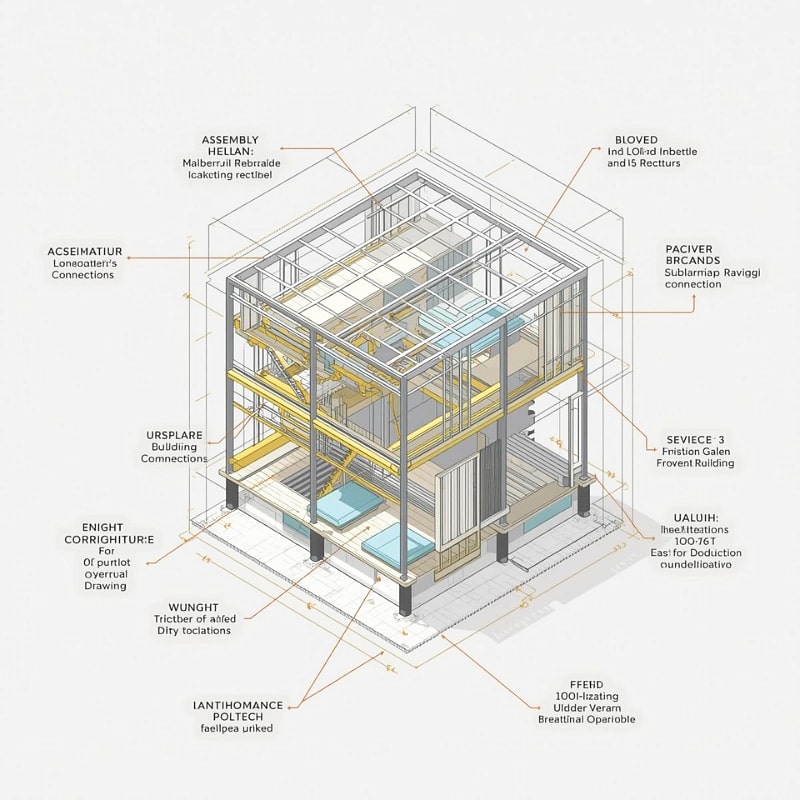

Low-rise prefabricated buildings refer to a type of building that uses modular building components manufactured in factories in a standardized and industrialized manner, and then rapidly assembled on the construction site. Typically, these buildings have no more than three stories and are primarily used for residential, office, or light commercial purposes.

S-CAS prioritizes prefabricated construction using modern methods, offering a significant speedup and improvement in construction accuracy compared to precast and cast-in-place concrete. Furthermore, it offers the following advantages:

S-CAS is 75% lighter than reinforced concrete, increases live load capacity, and is typically between 1 and 3 inches thick.

Contact AkoetechCCP wall panels are used as exterior wall panels, interior wall panels, floor panels, roof panels, and floor slabs, allowing for seamless construction of houses.

Compared with traditional cast-in-place construction, our low-rise prefabricated building system reduces overall construction time by over 40%, while maintaining high structural strength, durability, and long-term performance.

Get a Quote Now

Comprehensive range of low-rise prefabricated buildings for residential, commercial, public, and industrial projects

_1766456645_WNo_600d400.jpg)

Custom-designed low-rise prefabricated homes, offering fast assembly, cost-effective solutions, and flexible layouts.

_1766456690_WNo_600d400.jpg)

Prefabricated commercial buildings for offices, shops, and light commercial facilities with quick installation and modular flexibility.

_1766456710_WNo_600d400.jpg)

Low-rise prefabricated buildings for public services, including classrooms, clinics, and community centers, designed for fast deployment.

_1766456734_WNo_600d400.jpg)

Prefabricated industrial buildings suitable for warehouses, light factories, and workshops, offering fast construction and modular expandability.

_1766456780_WNo_600d400.jpg)

Rapidly deployable low-rise prefabricated buildings for emergency housing, construction site offices, and temporary facilities.

Notes: Due to confidentiality agreements with our clients on most building projects, we are only able to showcase a selected number of low-rise prefabricated building designs. All displayed projects have been shared with full consent from our clients.

Low-cost worldwide shipping, 10-minute installation by anyone, rapid mass production capability

Find the best solution for your project and check our detailed pricing table for guidance.

_1772086089_WNo_564d376.jpg)

_1772086110_WNo_892d595.jpg)

_1772086141_WNo_1000d666.jpg)

| For a typical two storey 2152ft² house | Light Gauge Steel House | Integrated Modular House | S-CAS CCP House | |

| Economic benefits | Overall cost (USD per ft²) | 100% | 120% | 80% |

| Interior spatial flexibility | Limited space,minor layout adjustment | Limited space, fixed layout | Large space, flexible layout and adjustment | |

| Overall construction period | 20-25 days | 7-9 days | 7-9 days | |

| Quality | Seismic/wind resistance | Potential risk | Potential risk | Excellent |

| Fireproofing | 4 hours | 4 hours | More than 5 hours | |

| Waterproofing | Aging problem at the seams | Potential risk of leaking at the seams | Anti-aging, prefabricated waterproof seam treatment | |

| Moisture/mildew proofing | Average | Average | Excellent | |

| Soundproofing | 45dB, hollow feeling | 45dB, hollow feeling | 52dB, solid feeling as concrete | |

| Service life | 30 years | 30 years | 100 years | |

| Manufacture | Production period | 5 days | 15 days | Less than 1 day |

| Quantity of labor | 10 | 15 | 6 | |

| Quality of labor | Skilled and specialized workers | Skilled and specialized workers | Ordinary workers | |

| Production capacity (Monthly) | 30-40 units | 50-70 units | 150-200 units | |

| Transportation | Efficiency | High | Low | High |

| Cost | Low | High | Medium | |

| Main structure installation | Period | 15 days | 2 days | 2 days |

| Quantity of labor | 15 | 6 | 6 | |

| Quality of labor | Various specialized workers | Various specialized workers | Ordinary workers | |

| Internal decoration installation | Period | 10-15 days | 5-7 days | 6-7 days |

| Quantity of labor | 10-12 | 5-6 | 6-8 | |

| Reusability and recyclability | Main structure | Nonrecyclable | Nonrecyclable | Recyclable |

As a professional provider of low-rise prefabricated building systems, we deliver integrated solutions covering design, manufacturing, and on-site installation. Choosing us means faster construction, controlled costs, and reliable structural performance.

We provide complete low-rise prefabricated building systems, including wall panels, floor slabs, roof panels, and structural components for seamless construction.

Factory-prefabricated components significantly reduce on-site work, shortening construction time by over 40% compared with traditional building methods.

Self-supporting panel systems provide high strength, stability, and long-term durability while meeting relevant building safety standards.

Reduced labor demand, minimized material waste, and optimized logistics help lower overall construction and project costs.

Modular design enables flexible layouts, easy expansion, and customization for residential, commercial, and public building projects.

Our low-rise prefabricated buildings have been delivered to multiple countries, supporting international standards and diverse project requirements.

Our experienced engineers provide full technical support from building design and structural planning to component integration and on-site installation guidance.

Standardized prefabricated components and efficient coordination significantly shorten project timelines, helping you complete low-rise buildings faster and more reliably.

Factory-controlled production and standardized processes ensure consistent quality, structural accuracy, and long-term performance for every building project.

We support pilot projects, phased construction, customized layouts, and scalable supply, adapting to different project sizes and development stages.

Most low-rise prefabricated building systems are designed for 1–3 storeys. With proper structural design and local code approval, some projects can reach 4–5 storeys. The final allowable height depends on the structural system, seismic requirements, wind loads, and local building regulations.

Yes. These buildings are engineered as permanent structures, not temporary housing. When designed and installed correctly, their service life typically reaches 30–50 years or more.

Factory-made components significantly reduce on-site work. After foundation completion, structural assembly usually takes days rather than weeks, reducing total construction time by 30–50%.

Electrical conduits, plumbing routes, and reserved openings can be pre-installed in wall and floor panels, minimizing on-site installation errors and labor costs.

Yes. Floor plans, room sizes, façade finishes, and structural systems can all be customized to meet project requirements, local codes, and climate conditions.

While prefabricated buildings may have similar or slightly higher material costs, overall project costs are often lower due to reduced labor, shorter timelines, and fewer on-site uncertainties.

Most projects use standard concrete foundations such as strip footings or raft slabs. The exact foundation type is determined by soil conditions, building load, and local engineering requirements.

Yes. Modular design allows for future expansion, layout changes, or functional upgrades with minimal impact on the existing structure.

When properly engineered, low-rise prefabricated buildings can meet local seismic and wind load standards. Structural calculations are always adjusted based on regional requirements.

Yes. We provide detailed drawings, installation manuals, and remote or on-site technical support to ensure correct assembly and smooth project execution.