Redefine city skylines with our advanced high-rise prefabricated buildings. Engineered for structural integrity and vertical efficiency, our solutions support multi-story residential towers, commercial high-rises, and mixed-use developments. From detailed planning and precision manufacturing to rapid on-site assembly, every stage ensures safety, durability, and modern architectural excellence. Explore how our high-rise prefabricated systems can maximize space, speed, and value for your next large-scale project.

High-rise prefabricated buildings are multi-story towers constructed from precision-engineered modular units. Typically ranging from 11 to 30 floors or more, these structures are designed to optimize vertical space while maintaining strict structural safety standards. They are ideal for residential skyscrapers, commercial office towers, hotels, and mixed-use high-rise developments where efficiency, durability, and safety are paramount.

S-CAS prioritizes prefabricated construction using modern methods, offering a significant speedup and improvement in construction accuracy compared to precast and cast-in-place concrete. Furthermore, it offers the following advantages:

S-CAS is 75% lighter than reinforced concrete, increases live load capacity, and is typically between 1 and 3 inches thick.

Contact AkoetechCCP wall panels are used as exterior wall panels, interior wall panels, floor panels, roof panels, and floor slabs, allowing for seamless construction of houses.

Compared with traditional cast-in-place construction, our low-rise prefabricated building system reduces overall construction time by over 40%, while maintaining high structural strength, durability, and long-term performance.

Get a Quote Now

Engineered high-rise buildings for residential towers, commercial skyscrapers, mixed-use developments, and industrial high-rises, combining vertical efficiency, safety, and sustainability

High-rise prefabricated residential buildings, typically 11–30 floors, designed for urban living with modular layouts, fast vertical construction, and enhanced structural integrity.

Designed for tall commercial use, these prefabricated buildings allow flexible multi-floor layouts, fast vertical assembly, and compliance with seismic and wind load standards.

High-rise public buildings engineered for rapid vertical deployment, offering 10–20 floors with modular classrooms, clinics, or community spaces.

High-rise industrial prefabricated buildings designed for warehouses and manufacturing, offering 5–15 floors with high load capacity and efficient modular assembly.

Prefabricated high-rise units for emergency housing, disaster relief, and construction site offices, engineered for fast vertical assembly and structural safety.

Notes: Due to confidentiality agreements with our clients on most building projects, we are only able to showcase a selected number of low-rise prefabricated building designs. All displayed projects have been shared with full consent from our clients.

Low-cost worldwide shipping, 10-minute installation by anyone, rapid mass production capability

Find the best solution for your project and check our detailed pricing table for guidance.

_1772095648_WNo_900d599.jpg)

_1772095905_WNo_900d600.jpg)

_1772096016_WNo_900d599.jpg)

_1772096217_WNo_900d599.jpg)

| Comparison Items | Cast-in-place Concrete System | Precast Concrete System | Traditional Bolt-welded Steel Structure System | S-CAS Prefabricated Steel Structure System |

| Economic Benefits | ||||

| Construction Period | 100% | 150% | 60% | 30% |

| Cost | 100% | 120-130% | 110-130% | 105-110% |

| Floor Area Ratio | 100% | 100% | 102-105% | 105-108% |

| Prefabrication Rate | 0% | 20%-40% | 50% | 95%-100% |

| Interior Space | Minor adjustments | Moderate adjustments | Flexible layout & adjustments | Flexible layout & adjustments |

| Quality | ||||

| Seismic Performance | Excellent | Doubtful | Excellent | Excellent |

| Structural Fire Resistance | More than 4 hours | More than 4 hours | Most cannot meet the standard in practice | More than 4 hours |

| Envelope Fire Resistance | More than 4 hours | More than 4 hours | More than 1.5 hours | More than 4 hours |

| Design | ||||

| Design Cost | 100% | 200% | 80% | 30-50% |

| Factory Manufacturing | ||||

| Number of Workers | / | 100% | 50% | 5-10% |

| Worker Requirements | / | Multiple trades, requiring professional workers | Multiple trades, requiring professional workers | Single trade, ordinary workers |

| Required Site Area | / | 100% | 60% | 20% |

| Production Capacity | / | 100% | 200% | 500% |

| Transportation | ||||

| Structure & Envelope Components | Raw materials cast-in-place | Heavy, short-distance transportation | Irregular shape, high transportation cost | Standardized components, low-cost global transportation |

| On-site Construction | ||||

| Scaffolding | Required | Required | Required | Not required |

| Wet Work | Extensive | Extensive | Moderate | None |

| Welding Work | Minor | Minor | Extensive | None |

| Coating Work | Extensive | Extensive | Extensive | None |

| Support/Template | Extensive | Extensive | Minor | Not required |

| Number of Workers | 100% | 50% | 50% | 10% |

| Worker Requirements | Multiple trades, requiring professional workers | Multiple trades, requiring professional workers | Multiple trades, requiring professional workers | Single trade, ordinary workers |

| Maintenance | ||||

| Structure | Requires maintenance every 3-5 years | Requires maintenance every 3-5 years | Requires maintenance every 3-5 years | No need (component powder anti-corrosion) |

| External Wall Envelope | Requires maintenance every 3-5 years | Requires maintenance every 3-5 years | Requires maintenance every 3-5 years | No need (self-cleaning surface function) |

| Demolition | ||||

| Blasting/Cutting/Crushing | Required | Required | Required | Not required |

| Dust/Noise Pollution | Extensive | Minor | Moderate | None |

| Reuse | ||||

| Building Components | Cannot | Cannot | Structure can, envelope cannot | Both structure and envelope can |

As a leading provider of high-rise prefabricated building systems, we deliver end-to-end solutions from advanced structural design and engineering to precision manufacturing and rapid on-site assembly. Partnering with us ensures safe vertical construction, optimized project costs, and robust performance for tall buildings and multi-story developments.

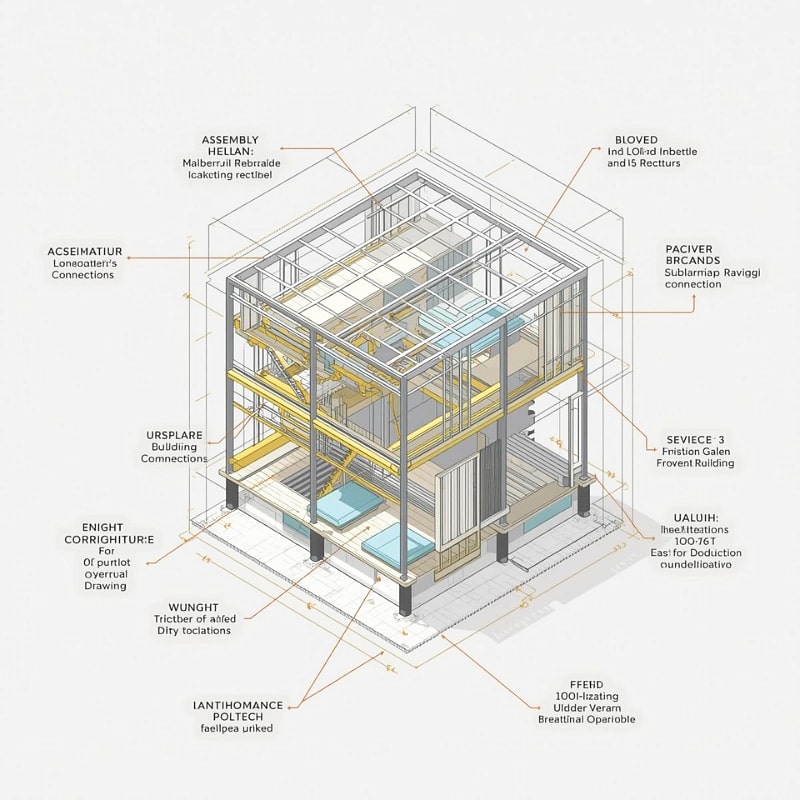

Our high-rise prefabricated solutions include reinforced load-bearing walls, floor slabs, roof panels, and structural modules, engineered for seamless assembly of towers up to 30 floors or more.

Factory-fabricated modules reduce on-site labor and enable installation of 3–5 floors per week, accelerating timelines for high-rise projects by 40–60% compared with traditional construction.

Designed for tall buildings, our systems meet seismic standards up to magnitude 8.0 and live load requirements of 2.5–3.0 kPa per floor, ensuring long-term stability, safety, and resilience.

Modular production minimizes material waste, optimizes logistics, and reduces labor costs, improving overall budget efficiency for high-rise residential, commercial, and mixed-use developments.

Modular units can be combined to create diverse floor plans, easily expanded vertically or customized to meet the functional requirements of high-rise residential, office, and public buildings.

Our high-rise prefabricated projects have been successfully delivered worldwide, adhering to international building codes and supporting complex multi-story construction demands.

High-rise prefabricated buildings are typically designed for 11–30 floors. The maximum height depends on structural design, seismic and wind load requirements, and local building codes. With advanced engineering, some projects can even exceed 40 floors using reinforced modular systems.

Yes. These buildings are engineered as long-term structures. When designed and installed according to international standards, their service life can exceed 50–60 years, with excellent performance for tall, multi-story applications.

Prefabricated modules significantly reduce on-site labor. After foundation completion, structural assembly can proceed at 3–5 floors per week, shortening overall construction time by 40–60% for high-rise buildings.

Yes. Electrical conduits, plumbing, HVAC pathways, and pre-cut openings can be embedded into wall and floor modules, minimizing on-site errors and labor for complex vertical construction.

Absolutely. Floor plans, apartment or office sizes, façade finishes, and structural configurations can all be tailored to project specifications, local codes, and climate conditions.

Although high-rise prefabricated buildings may have slightly higher material costs, total project costs are often reduced due to faster assembly, lower labor requirements, and minimized on-site uncertainties.

Foundations typically include reinforced concrete raft slabs, pile-supported bases, or deep foundation systems depending on soil and structural load. Engineers determine the optimal foundation for each high-rise project.

Yes. The modular design allows for vertical or horizontal expansion, interior reconfiguration, and functional upgrades, while minimizing disruption to existing structures.

Properly engineered high-rise prefabricated buildings comply with stringent seismic and wind-load standards. Structural calculations are customized for regional requirements, ensuring safety and stability for tall constructions.

Yes. We provide detailed construction drawings, step-by-step manuals, and remote or on-site technical assistance to ensure accurate assembly and smooth project delivery for high-rise buildings.